Tutorials (Wednesday, 18.09.2019)

18.09.2019

13:30 – 15:00

German

Layouterstellung und -konfiguration im Simulationswerkzeug Visual Components

Jan Hermann, DUALIS GmbH IT Solution, Germany

Bei der Fabriksimulation geht es darum, zu visualisieren, wie die Dinge in der realen Welt funktionieren könnten. Das heißt, Sie arbeiten an einer oder mehreren Lösungen. Eine Lösung könnte die Integration von Robotern in einen Fertigungsprozess sein. Eine weitere Lösung könnte das Erstellen von Projektvorschlägen für den Verkauf von Produkten sein. Schließlich möchten Sie vielleicht das, was Sie tun, verbessern und die Simulation nutzen, um dies zu erreichen. Diese Lösungen müssen nicht viel Zeit in Anspruch nehmen, setzen nicht immer Sachkenntnis voraus und müssen auch nicht schwierig sein. Sie können viele verschiedene Aspekte der Industrie mit einer Bibliothek von vorgefertigten Komponenten simulieren, die Aufgabenfolgen ausführen. In diesem Kurs lernen Sie, wie Sie einfache und komplexe Prozesse mit Komponenten aus der Works-Bibliothek in der Simulationsplattform Visual Components simulieren können.

18.09.2019

13:00 – 15:00

English

Data driven companies need predictive analytics - Simulation platform versus Tooling

Fred Jansma, Chief Technical Officer, INCONTROL Simulation Solutions, Germany

Companies capture more and more data and it plays a major role in (re)design and cost reduction programs and in running daily operations. During the presentation INCONTROL will present how we made the evolution from providing simulation studies to implementing applications that use simulation as their back-bone. We will also touch some of the trends we see for the near future and the impact that it has on the software we provide to our customers in Urban Development and Discrete Manufacturing & Logistics.

Source: © Fred Jansma

18.09.2019

15:15 – 16:45

English

Designing lean Production with Simulation

Dr. Chawalit Jeenanunta, Sirindhorn International Institute of Technology, Thailand

The objective of this workshop is to introduce the concept of designing lean Automation using the production simulation on Cloud, GD.findi, by Lexer Research Inc. We will build simple automation model and work on the simulation result to interactively navigate detailed simulation record data using production cockpit and output visualizer, Material Flow Chart. Participants will learn how to design the initial work in process and machine cycle time that could improve the efficiency of the production line. Moreover, participants could get hand on with the teaching material that they could also adopt for teaching an introduction simulation class for a semester long. At the end of the workshop, the advance concept on optimization and scheduling on cloud utilizing the API to interface with GD.findi Parameter Variation Driven Optimization (PVDO) will also introduced.

Source: © Dr. Chawalit Jeenanunta

18.09.2019

15:15 – 16:45

English

Designing lean Production with Simulation

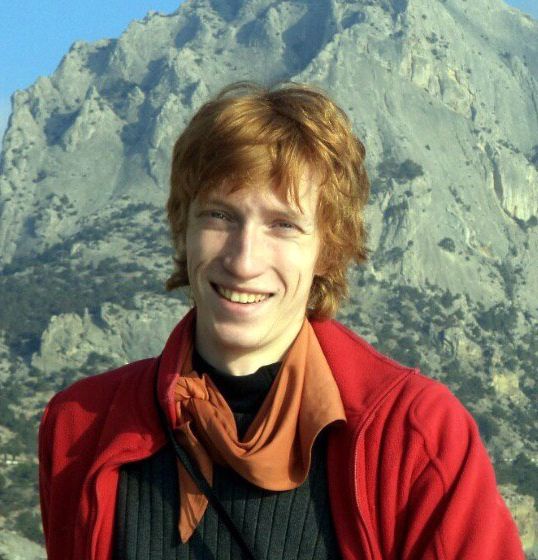

Gregory Monakhov, Senior Technical Support Engineer, The AnyLogic Company, USA

Part A: anyLogistix Applications to Supply Chain Simulation and Optimization

In today’s world, the only way to stay ahead of your competitors, or even to be competitive at all, is through innovation. Supply chain is not an exception to this rule. Analytical optimization and dynamic simulation are two commonly used technologies to solve complex supply chain problems, including such issues as supply chain digital transformation. However, there has been a lot of confusion around the terms “optimization” and “simulation” in the industry – they are often misinterpreted by people and companies offering supply chain solutions. We will share our view on these techniques, and on how to be innovative by employing both optimization and simulation to become lean and agile.

Part B: AnyLogic Material Handling Library and AnyLogic Cloud for New Disruptive Technologies Available with Industry 4.0

The workshop is built around the new AnyLogic Material Handling Library. The library simplifies the simulation of complex manufacturing systems and operations. It can be used to design detailed models of production and storage facilities and manage material workflows inside four walls. The digital factory model, created with the material handling simulation toolkit, can help test and optimize production, transportation, and inventory policies, as well as reduce possible errors while introducing innovations to existing operations, or integrating modern technologies. In conveyor network models, created with the Material Handling Library, users can apply default or set up custom routing strategies for material items, industrial robots, manufacturing machines, and operators. Simulated AGVs and other transporters automatically avoid collisions, detect possible deadlocks, and resolve them.

Source: © Gregory Monakhov

18.09.2019

14:00 – 15:30

German

Guided Tour VR-Lab / Geführte Tour VR-Labor

M.Sc. Mario Lorenz, Technische Universität Chemnitz, Germany

Via a short walk over the campus, this guided tour takes you to the VR-Lab of the Chemnitz University of Technology where you will be immersed in Virtual and Augmented Reality technology. You will enter the Holodeck (5-sided CAVE), get hands-on a virtual surgery and experience the magical sand box.

Nach einem kurzen Spaziergang über den Campus gelangen Sie zum VR-Lab der Technischen Universität Chemnitz, wo Sie in die Virtual- und Augmented-Reality-Technologie eintauchen. Sie betreten das Holodeck (5-Seiten CAVE), nehmen an einer virtuellen Operation teil und erleben den magischen Sandkasten.

Source: © Mario Lorenz

- Home

- -

- Papers

- -

- Program

- -

- Gallery

- -

- Supporters

- -

- Exhibition

- -

- Venue

- -

- Past Conferences

- -

- Contact